Cryogenic valves

Committed to the future

Perfect control

At BUTTING CryoTech, we have been producing vacuum-insulated transfer systems for cryogenic liquids (LNG, LH2, LOX, LN2, LAR) since 1984. Since 1990, we have expanded our range of services to include the manufacture of cryogenic valves. From our factory site in Bavaria, we supply many of the world's most renowned companies in industry, high-tech and research.

Since then, BUTTING CryoTech has delivered more than 25,000 pneumatic and manual valves for the control of cryogenic transfer systems. Our valves in sizes from DN6 to DN250 are certified according to ADR/RID 2021 and approved for the transport of media by road in accordance with Directive 2010/35/EU (TPED).

Valves for all areas of application

- Functions: Shut-off valve, control valve, non-return valve

- Nominal sizes: DN6 to DN250

- Pressure ratings: Depending on type up to PN400

- Types of construction: Straight, angled and Z-shaped passage

- Actuation: Manual or with pneumatic diaphragm actuator

BUTTING CryoTech

We set standards

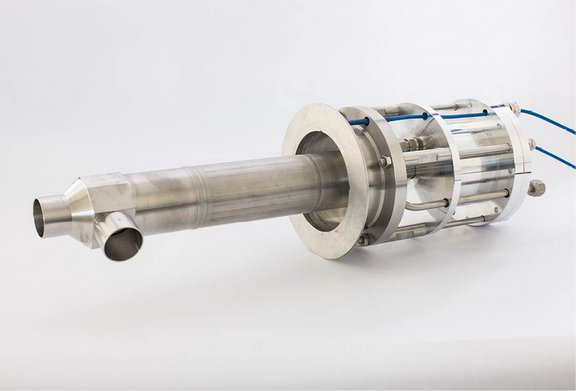

The integration of valves requires precise adaptation to the insulation system. For this reason, only valves with a particularly long stem length are selected for cryostats in order to minimise heat input. We also supply control technology that is fully customised to the system.

Another innovative key element of BUTTING CryoTech is the modularity of our valve actuators, which enables flexible integration into existing systems. By developing valve actuators specially tailored to the requirements of cryogenic applications, we have already set new standards in terms of flexibility and adaptability.

Benefit from our expertise!

Groundbreaking developments

The development of valves for cryogenic applications has the task of ensuring minimal energy losses and excellent insulation during media transport. BUTTING CryoTech masters these challenges through intensive research and development and continues to find new solutions that meet the specific requirements of different applications.

One of BUTTING CryoTech's pioneering developments is the introduction of an electrically driven valve for liquid hydrogen, the innovative technology of which goes far beyond conventional pneumatic valves. In addition to highly precise control of media flows, it offers considerable advantages in terms of efficiency, cost optimisation and safety.

Comprehensive service

In addition to production, we at BUTTING CryoTech cover the entire range of services from simulation technology and engineering to material testing and the installation of our systems, documentation and other services. Our aim is to play an active role in shaping the mobility of the future and to drive forward the development of sustainable technologies.