Clad pipes

Clad pipes for the most stringent requirements

Impressively consistent

BUTTING uses clad materials when it comes to pipes with a maximum load-bearing capacity. Project-specific, material combinations in line with the requirementsfor every area of application guarantee high internal corrosion resistance and high external pressure resistance, along with cost savings of up to 40 % compared to solid-wall pipes.

Leading through experience

BUTTING is the global market leader for clad pipes. These are the first choice in industry when high dynamic loads, high pressures and a high aggressiveness of the transported media prevail. Companies worldwide rely on quality from BUTTING.

We have been processing clad materials into pipes and piping components for almost 40 years. As the global market leader for clad pipes, we manufacture mechanically lined BuBi® pipes (4" to 26"), glued mechanically bonded GluBi® pipes (6" to 18") and metallurgically clad pipes (4" to 48") at our site in Knesebeck. But we can also take on your individual challenge: together with you, we develop solutions for component parts.

Mechanically vs. metallurgically clad

In casw of mechanically clad pipes, a longitudinally welded stainless steel inner pipe is inserted into an outer pipe made of carbon-manganese steel using mechanical processes. The advantages of mechanically clad pipes:

- Cost savings of up to 40 % compared to solid-wall pipes

- High internal corrosion resistance with high external pressure resistance

- Project-specific, material combinations in line with the requirements

Metallurgically clad pipes are manufactured from appropriate plates in which the metal layers are metallurgically bonded by a diffusion bridge. The advantages of metallurgically clad pipes are

- Reduction in wall thickness

- Cost benefits even with small dimensions compared to solid-wall pipes

- Weight saving

- Wide range of material combinations

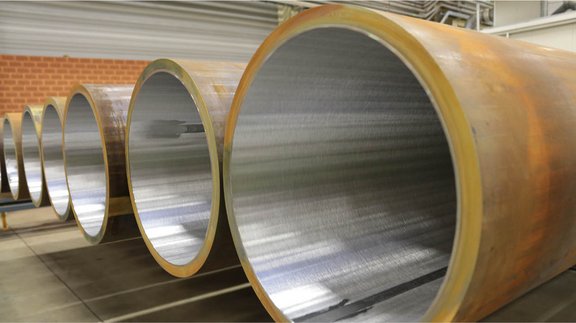

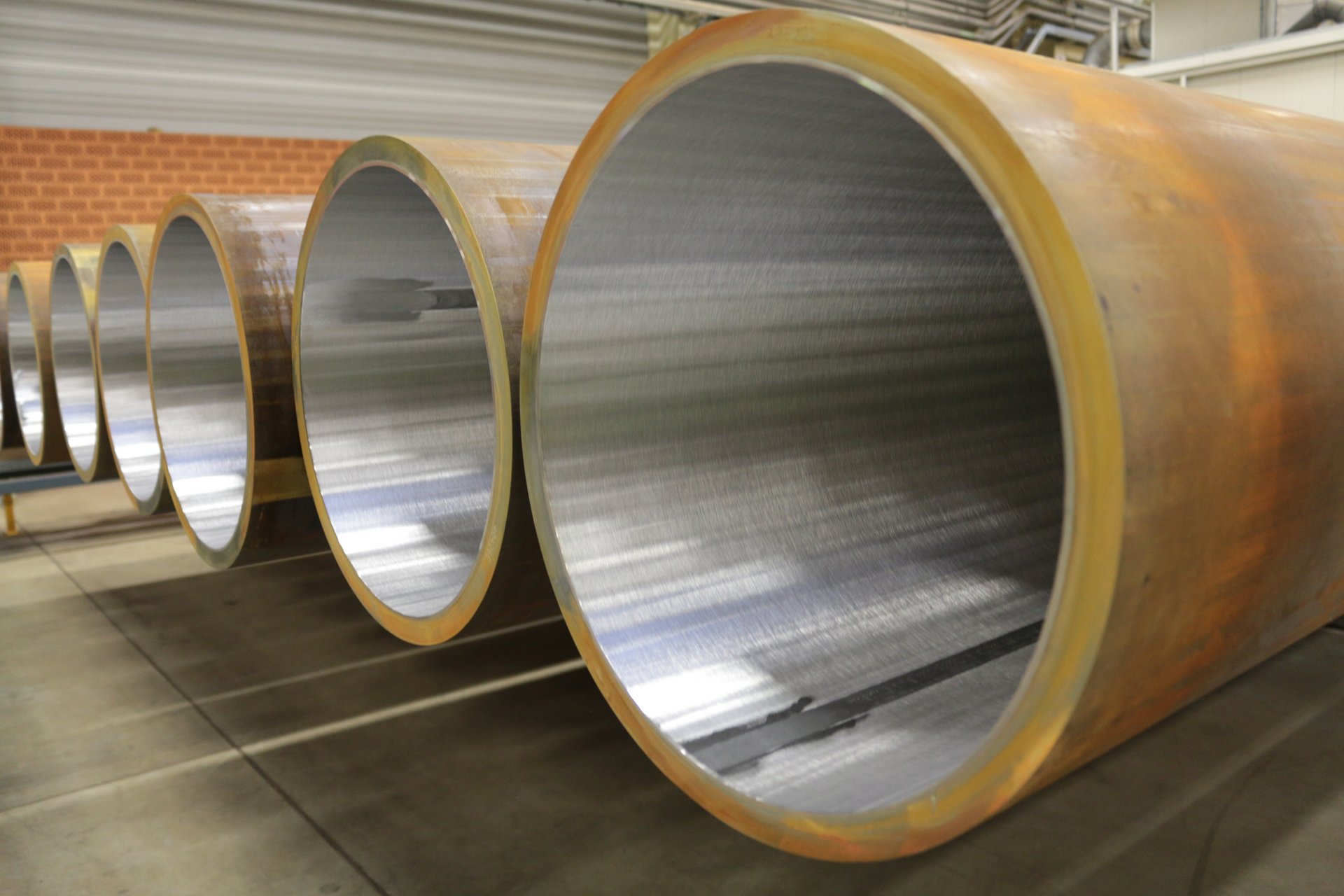

Mechanically lined pipes

BUTTING bi-metal pipe (BuBi® pipe)

In the early 1990s, BUTTING developed the mechanically clad BUTTING-bi-metalpipe- BuBi® pipe for short. In this process, a corrosion-resistant BUTTING stainless steel pipe is inserted into a carbon-manganese steel pipe followed by mechanical bonding using a hydroforming system. The BuBi® pipe combines the outstanding strength and toughness properties of carbon-manganese steels with the corrosion resistance of stainless steels. BuBi® pipes are mainly used successfully in the oil and gas extraction industry for conveying highly corrosive media and are used as line pipes, risers or SCR pipes.

Technical details at a glance:

- Dimensional range OD 114.3 (4") to 660 mm (26")

- Production lengths up to 24 m (up to 12 m without circumferential weld)

- Manufactured in accordance with API, ASTM, DNV or ISO

- Suitable for S-lay, J-lay, bundle or reeling installation methods

Mechanically lined pipes

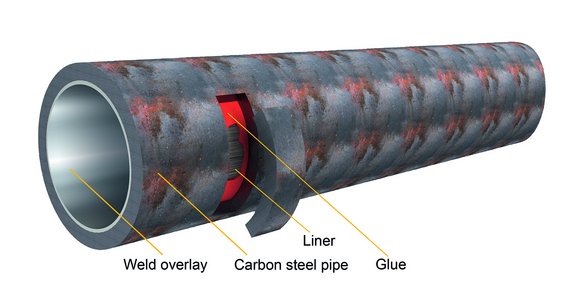

GluBi® pipe

With the innovative GluBi® pipe, we have developed a glued mechanically bonded pipe. A BuBi® pipe is provided with a special adhesive between the carbon-manganese steel and the corrosion-resistant liner so that it can be laid using the reel-lay method without increasing the wall thickness of the corrosion-resistant liner.

Technical details at a glance:

- Dimensional range OD 168.3 mm (6") to OD 457.2 mm (18")

- Manufactured in 12 metre lengths

- Manufactured in accordance with API and DNV

- Suitable for all installation methods, economical for reeling and J-lay installation methods

Proven all-rounder

Metallurgically clad pipe

As regards BUTTING pipes made from metallurgically clad plates, the metal layers are firmly bonded by a diffusion bridge. As a result, they combine high strength and special surface properties. They are suitable as SCR, riser, process or line pipes for laying in the S-lay, J-lay, bundle or reeling method.

Technical details at a glance:

- Dimensional range OD 114.3 (4") to 1 219 mm (48")

- Wall thicknesses up to 70 mm

- Maximum wall thickness / outer diameter ratio 1:10

- Various material combinations

- Production lengths of up to 24 m (6 m or 12 m lengths without circumferential weld)

- Suitable for S-Lay, J-Lay, bundle or reeling installation methods

New development

BUTTING SmartClad

The BUTTING SmartClad is a cost-effective alternative to conventional metallurgically clad pipes and, in particular, to BuBi® pipes with a large outsidediameter. The metallurgically clad pipe is used as the base material, whereby the high-quality cladding having a thickness of just 1.5 mm is sufficient. By comparison, metallurgically clad pipes are usually 2.5 to 3 mm thickness.

Do you desire a cladding thickness of 3 mm at the pipe ends in order to be able to guarantee the necessary tolerances through machining? We achieve this by a 3 mm weld cladding at the pipe ends, as is standard in the production of mechanically clad BuBi® pipes. For the BUTTING SmartClad, we thus combine the manufacturing processes of metallurgically and mechanically clad pipes.

Your advantages at a glance:

- Cost savings thanks to the reduced wall thickness of the high-alloyed cladding

- Reduction of nickel consumption by 50 per cent

- Many years of experience in the manufacturing process

- Guaranteed resistance to pressure and corrosion

- Guaranty of optimal further processing thanks to tight tolerances and proven manufacturing processes

- No changes to subsequent production steps in the downstream value chain

Quality from a single source

Clad spools

Optimise your piping system by using ready-to-install spools from BUTTING. The combination of our clad pipes with weld-clad semi-finished products such as flanges, bends, T-pieces or reducers ensures consistently optimum quality and is particularly economical thanks to easier installation at the assembly site.

Advantages of ready-to-install clad spools:

- Use of high-quality semi-finished products from BUTTING production

- High degree of automation and high reproducibility

- First-class processing quality, e.g. thanks to consistent quality assurance

- Savings due to less welds and assembly times on the construction site

"In order to meet the steadily increasing demand in the mechanically clad pipe segment, we have doubled our production capacity at the Knesebeck site since 2019 and set up a second production line. This results in a new total production capacity for mechanically clad pipes of over 200 kilometres per year."