Industries

Food industry

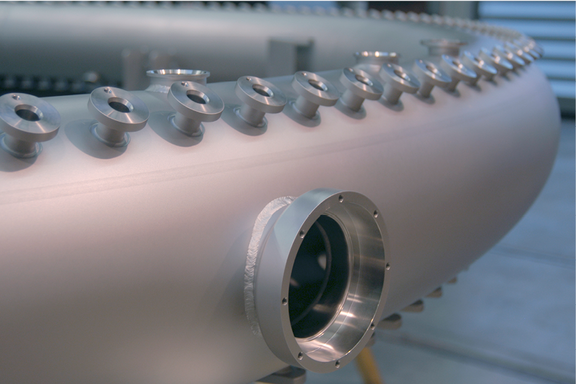

BUTTING manufactures longitudinally welded stainless steel pipes in accordance with DIN EN 10357 for hygienic and safe food processing with the highest requirements.

We protect what nourishes

Piping according to DIN EN 10357

BUTTING has been manufacturing pipework for the food industry for decades - in accordance with DIN EN 10357 and beyond. Our full-bath pickled pipes stand for hygienic surfaces, high corrosion resistance and long-lasting quality - for safe processes you can rely on.

Let us do the talking!

Are you looking for a reliable partner for hygienic pipe systems? Then BUTTING is the right partner for you! We will work with you to find the ideal solution for your requirements.

BUTTING tubes for the food industry

Our services at a glance

- Pipe storage: fast delivery of longitudinally welded pipes in accordance with DIN EN 10357

- dimensions: DN 15 to 300

- Versions: BC or BD

- Other dimensions, special geometries and tolerances as well as CC and CD versions on request

- Materials: 1.4301 (TP 304), 1.4307 (TP 304L), 1.4404 (TP 316L)

- Roughness: Ra < 0.8 / 1.6 µm or Ra < 0.8 / 0.8 µm in relation to inner surface and weld seam area

- Chemical full bath pickling of all pipes

Your security counts - we develop your solution: cleanly, reliably, in partnership!

You can rely on our comprehensive support and excellent advice. Get in touch with us directly. We look forward to your individual challenge!