Aircraft & Aerospace

For the most demanding applications

Precision, lightweight construction, reliability

BUTTING manufactures high-quality stainless steel and titanium components for the aerospace industry - from tubes to ready-to-install assemblies. Our components fulfil the highest requirements in terms of quality, weight and safety - for use under extreme conditions.

Application examples

Our stainless steel and titanium components are used in numerous aerospace applications - wherever low weight, precision and absolute reliability are required.

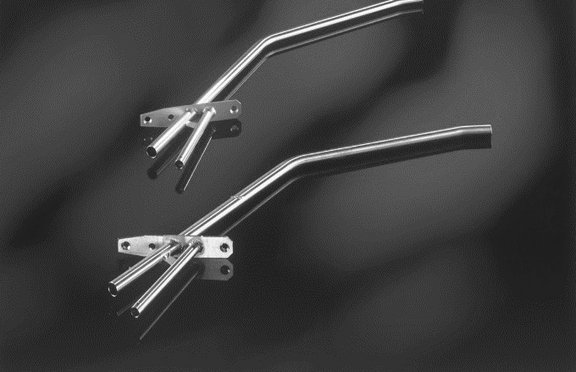

- Titanium tubes and ducting

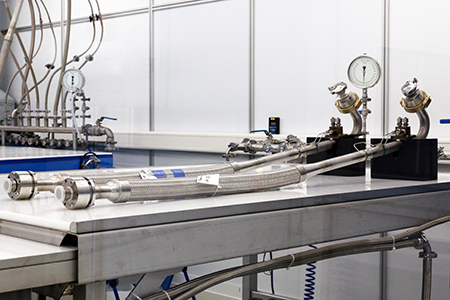

- Cleanroom production for sensitive aerospace-specific components

- Specialised components for aerospace applications, e.g:

- Cryogenic pipes, valves and connections for hydrogen refuelling

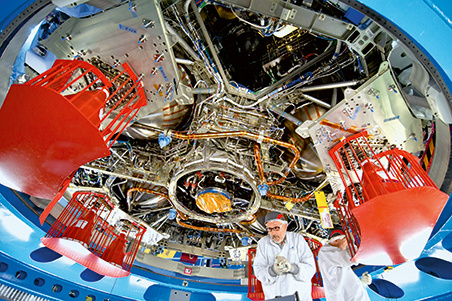

- Pipe parts for launch systems (e.g. Ariane 6) and space capsules (e.g. ORION mission)

- Water tanks for aeroplanes

Our strengths

With state-of-the-art production technology, many years of experience and comprehensive quality assurance, BUTTING offers reliable solutions for demanding aerospace projects.

- In-house production with a wide range of technologies

- Experienced in international aerospace projects

- Documented quality and traceability

Decades of experience

We have been producing a wide range of products for the aerospace industry since the mid-1970s. Our products are used in Airbus passenger and cargo aircraft, in the Ariane space programme and in space stations and vehicles. We also manufacture components for ground and test equipment.

Committed to strong networks

As a reliable partner to the aerospace industry, BUTTING is active in various specialist networks. Through our memberships in organisations such as BavAIRia, Hamburg Aviation and Hanse Arospace, we maintain an intensive exchange with industry, research and politics. This allows us to stay close to the latest developments in the industry at all times and actively shape innovations.

For the highest demands

Certifications

BUTTING fulfils the high quality requirements of the aerospace industry - in accordance with international standards and with industry-specific approvals.

- DIN EN 9100

- Cleanroom of cleanroom class DIN ISO 14644-1 cl. 7 / US Fed. STD.: 10 000

- Accredited laboratory in accordance with DIN EN ISO 17025:2005

- Welding operation in accordance with DIN EN ISO 3834-2

- Qualification of welders in accordance with EN ISO 24394-B (stainless steel) and EN ISO 24394-C (titanium)

- Non-destructive testing:

- DIN EN ISO 17637: visual inspection of fusion-welded joints

- DIN EN ISO 3452: Dye penetrant testing

- DIN EIN ISO 17636-1 and DIN EIN ISO 17636-2: Radiographic testing

- Pressure and leakage test according to customer requirements

- 3D measurement