Test technology & laboratory

Always a leader

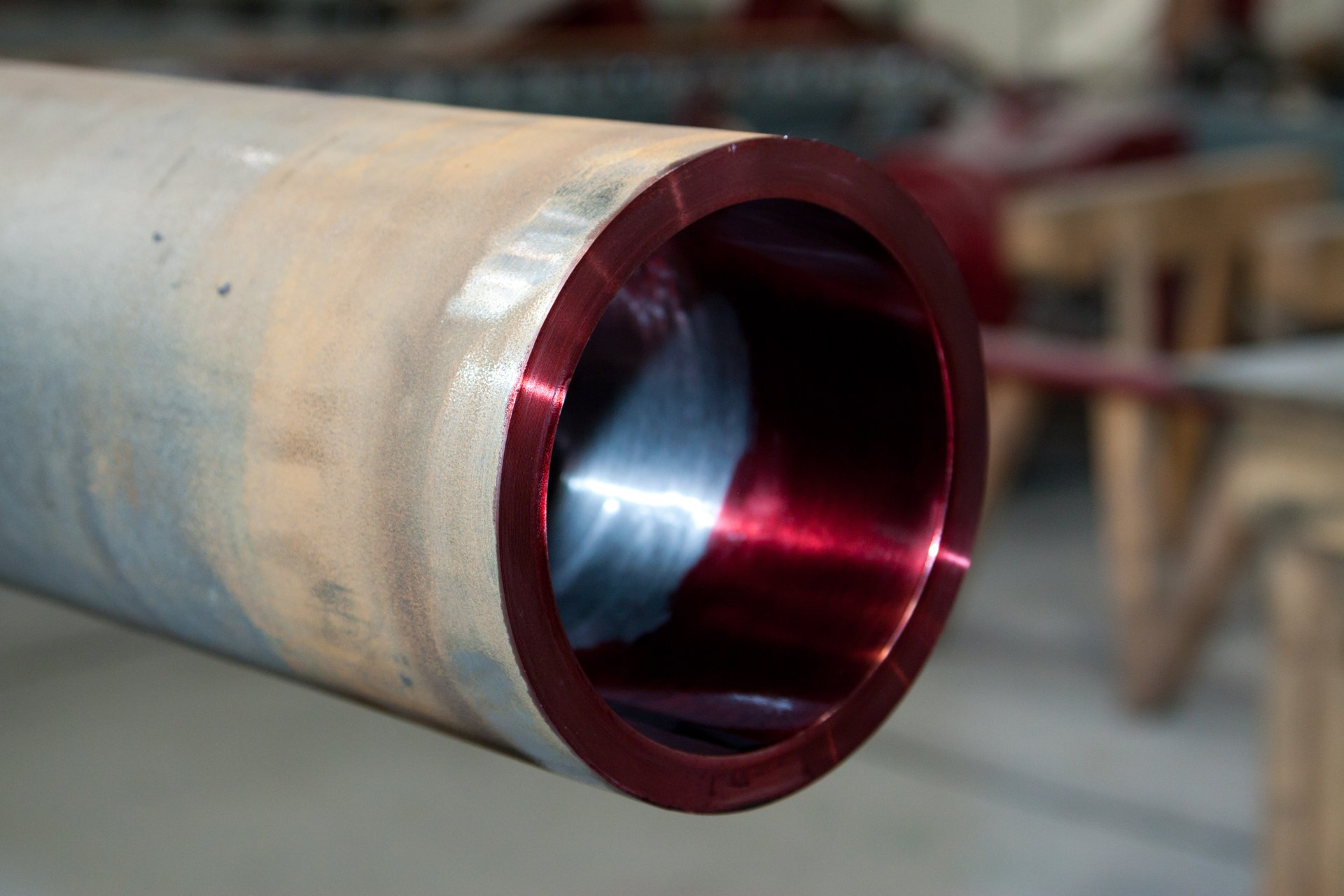

Quality inspection at BUTTING

BUTTING is a pioneer in quality inspection and the documentation of production results. The use of innovative X-ray technology was already routine for us in 1962, and we have been monitoring and documenting our entire production process since 1988 in order to guarantee long term traceability of every product.

Safety now and in the future

At BUTTING, we invest sustainably and permanently in quality assurance, particularly in the optimisation of our in-house testing. Through the consistent certification and accreditation of our various testing procedures, we also emphatically ensure and prove the consistently high quality and reliability of our products and services.

Large selection

Application of state-of-the-art testing methods

Companies worldwide rely on BUTTING's traditionally high product quality for demanding projects. We offer a wide range of destructive and non-destructive testing methods.

Non-destructive testing

- Conventional X-ray inspection (film technique)

- Digital X-ray inspection

- Manual and automated ultrasonic testing (e.g. of longitudinal weld, cladding welds, pipe bodies)

- Eddy current testing

- Water pressure testing

- Visual inspection incl. endoscopy

- Confusion testing (X-ray fluorescence analysis, optical emission spectroscopy)

- Roughness measurement

- Leak / crack testing using helium leak testing, dye penetrant testing and magnetic particle testing

- Strain gauges (DMS)

- Mobile hardness testing and metallography

- Destructive testing

Destructive testing

- Corrosion testing

- Hardness test (Vickers and Rockwell)

- Tensile test at room temperature

- Tensile test at elevated temperatures (up to 1,000 °C)

- Tensile test at low temperature (down to -196 °C)

- Notched bar impact test at room temperature

- Notched bar impact test at low temperature (down to -196 °C)

- Technological tests (e.g. bending, expansion test)

- Shear test

- Metallographic analyses

- Ferrite determination

- Scanning electron microscopy

- Spectral analysis

- Corrosion tests

Corrosion tests

- Pitting corrosion test / Pitting test

- ASTM G48 Method A

- ASTM A923 Method C

- Intergranular corrosion test

- DIN EN ISO 3651-2 Method A (Strauß test)

- DIN EN ISO 3651-2 Method B

- DIN EN ISO 3651-2 Method C

- ASTM A262 Method A

- ASTM A262 method B (Streicher test)

- ASTM A262 method C (Huey test)

- ASTM A262 method E (Strauß test)

- ASTM G28 Method A

- SEP 1877 Method II

Partner for innovative solutions

Hillger NDT

With Hillger NDT GmbH, which we integrated into the BUTTING Group as an independent company in 2019, we were able to gain the expertise of a renowned partner for innovative solutions and testing tasks in the field of non-destructive testing. Since then, Hillger has been supporting our internal specialists in all areas of research and development.

Hillger NDT GmbH develops and sells ultrasonic imaging inspection systems as an upstream development unit for the production and quality assurance at BUTTING. One focus is on aerospace technology. Thanks to the innovative strength of this partner, we are constantly expanding our outstanding quality assurance with additional non-destructive testing methods.