Further processing

Variety and precision

Our production centre

For years, the BUTTING Group has been a reliable supplier of special ready-to-install components and precision parts for a wide range of industries worldwide. That is why our core statement "More than pipes" also stands for our extensive possibilities for processing pipes or sheet metal into new, customised products.

Technology at the highest level

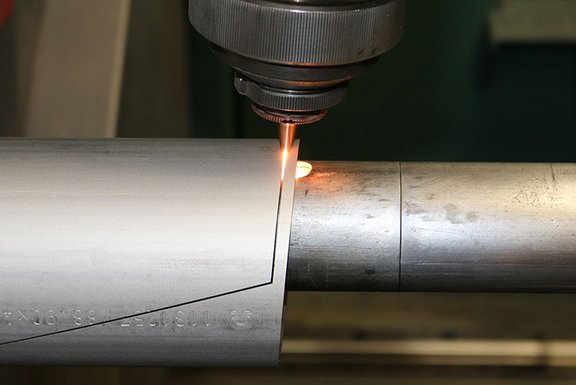

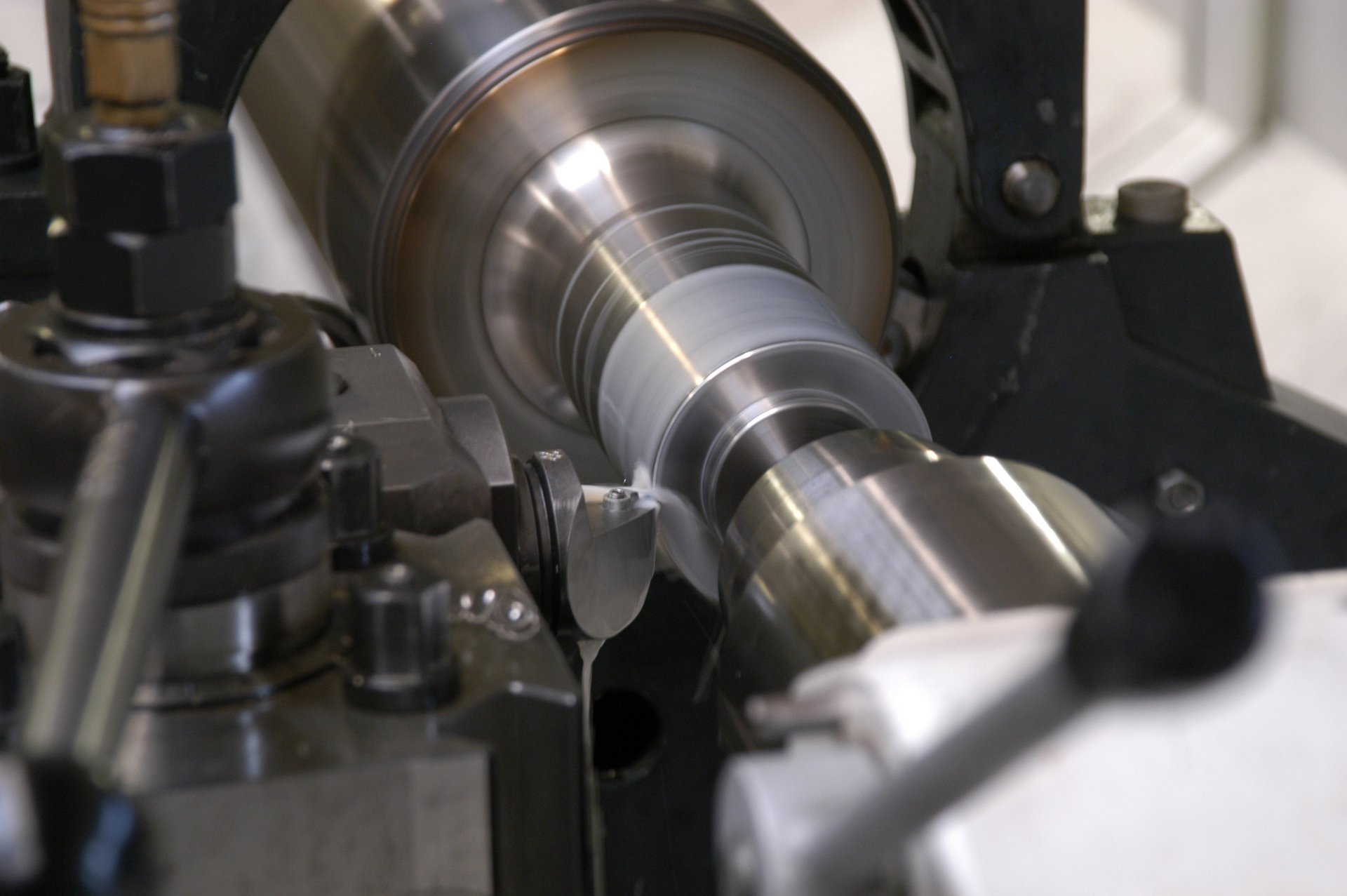

Our production centre is equipped with state-of-the-art 3D laser technology, robot welding technology, forming, grinding and CNC turning and milling technology. Our continuous investment in this equipment ensures that we fulfil your requirements for our product and service portfolio at the highest level and with state-of-the-art technology at all times.

We invest for you

At BUTTING, we continue to pursue the expansion of our further processing and are constantly opening up new possibilities for you by combining different production processes and process applications. This enables us to realise your special product requirements quickly, economically and reliably while maintaining the highest quality standards.

Customised product solutions

Solutions for many industries

At BUTTING, we manufacture according to the specific requirements of your industry, in every technically possible design and in accordance with all current regulations. We have the right solution for each of your projects.

Chemistry

Energy

Vehicle construction

Food

Aerospace

Maritime economy

Mechanical and plant engineering

Paper and pulp

Pharmaceuticals